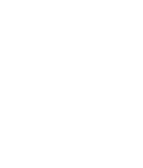

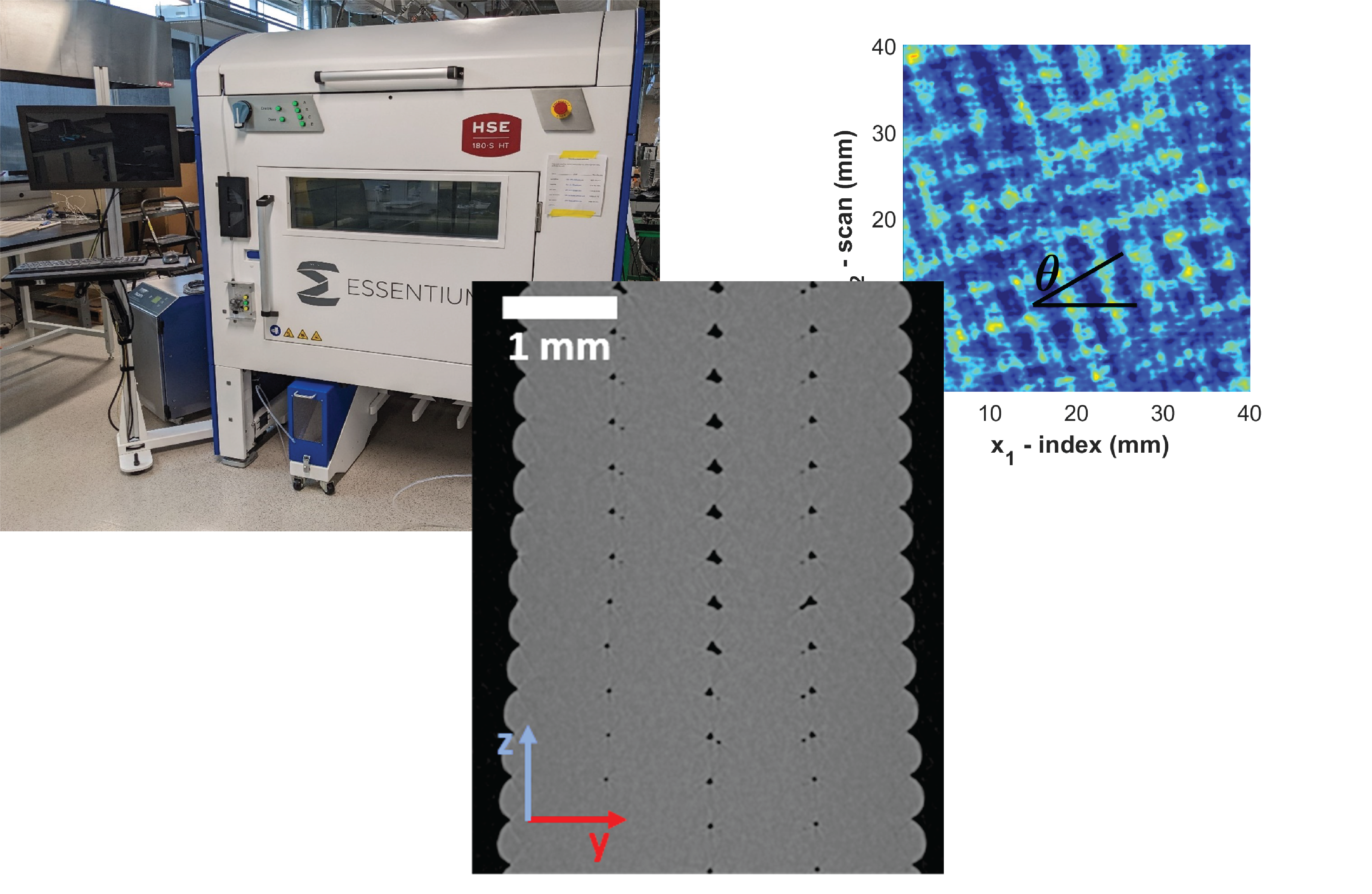

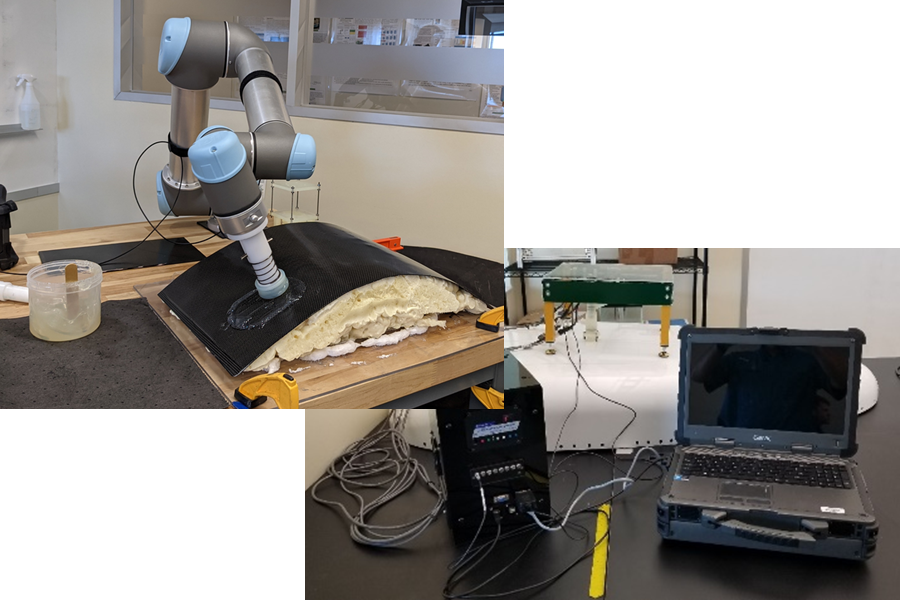

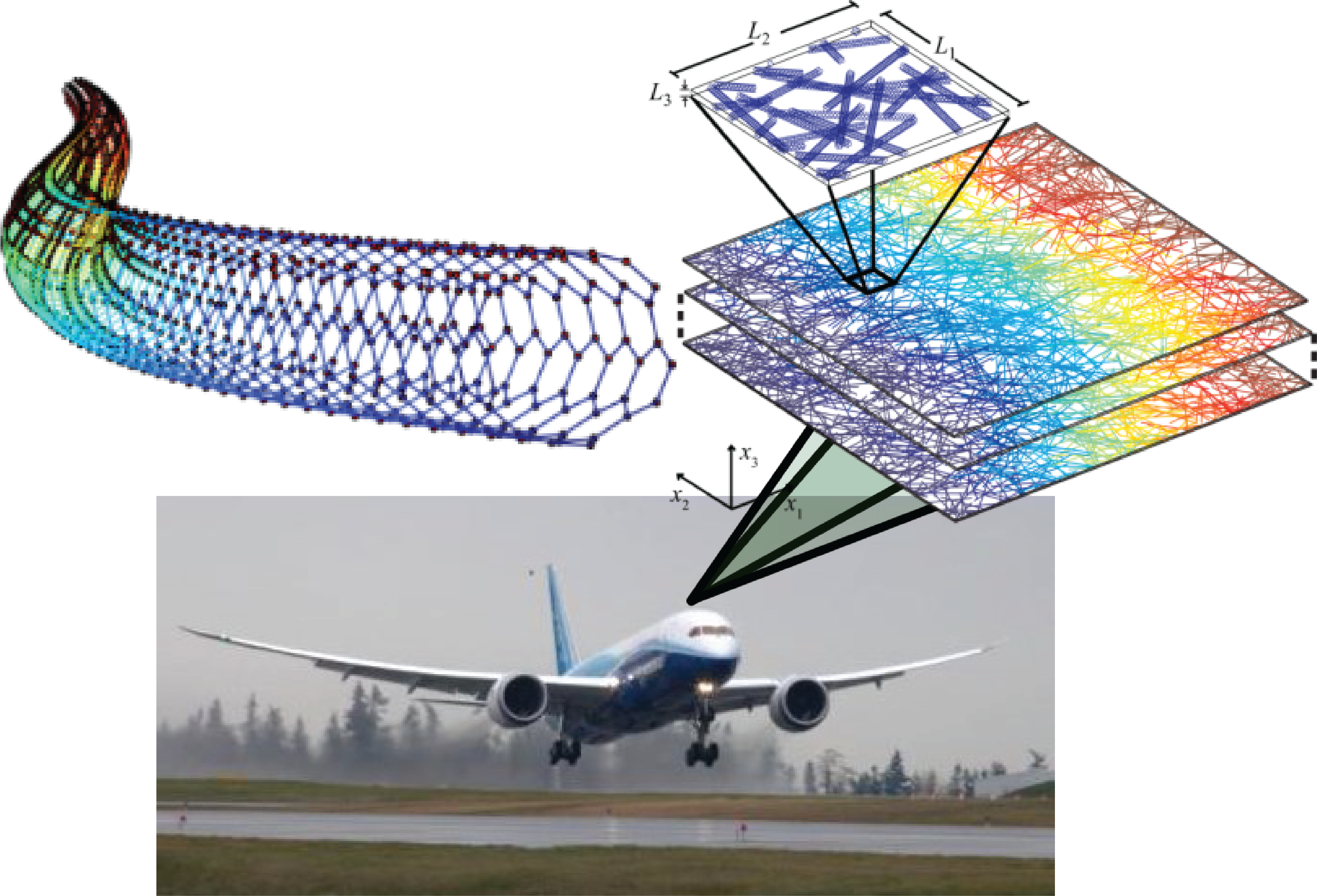

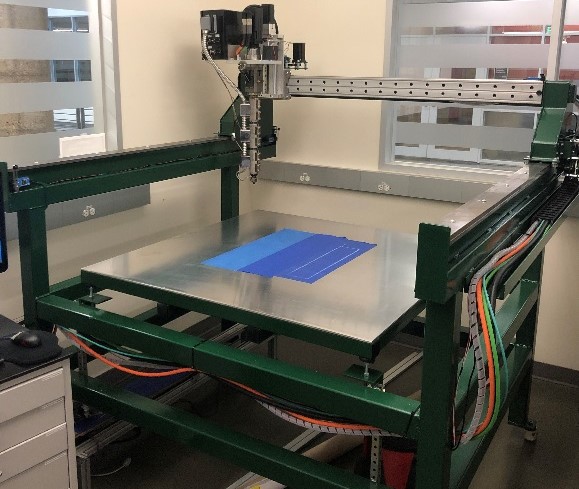

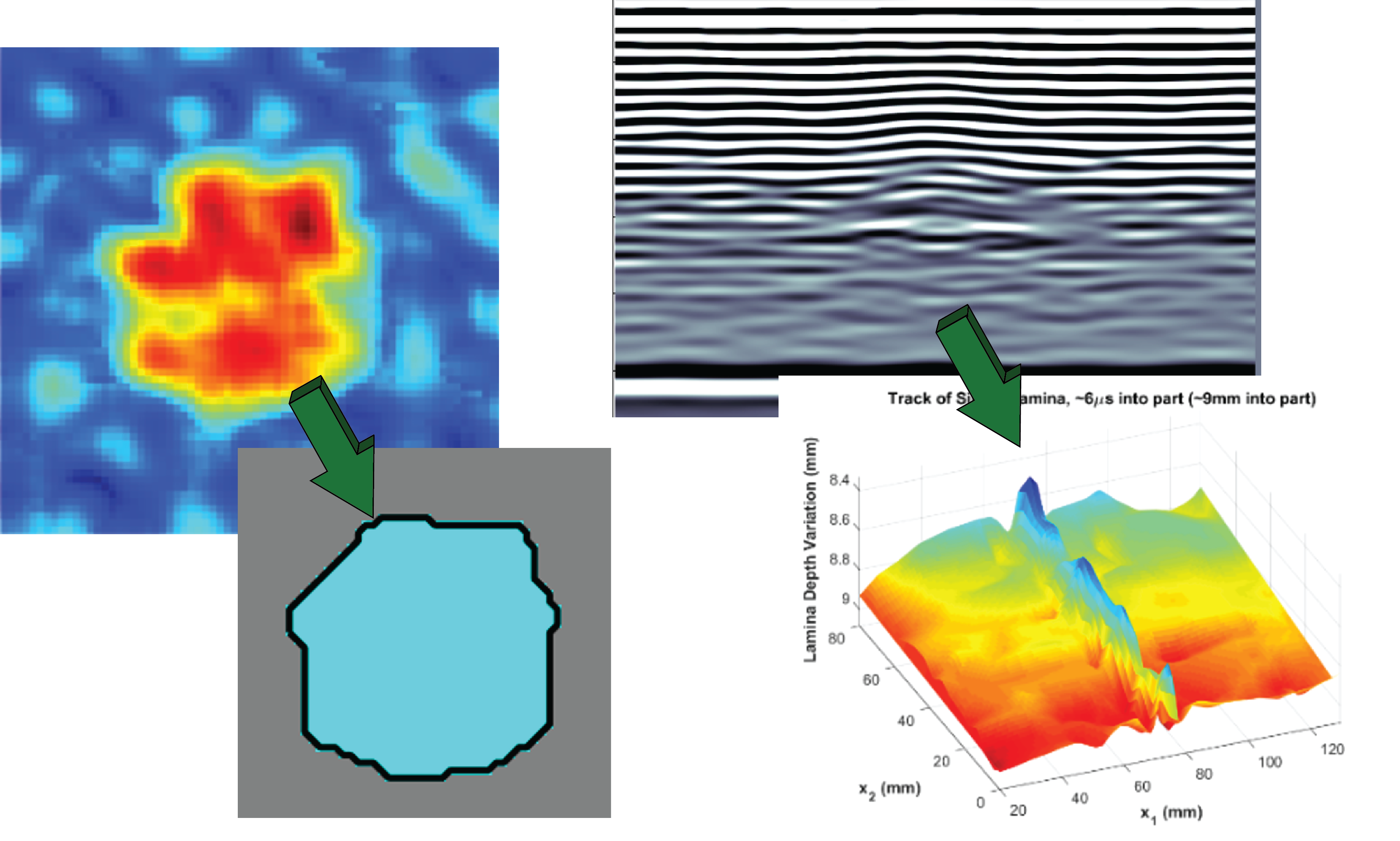

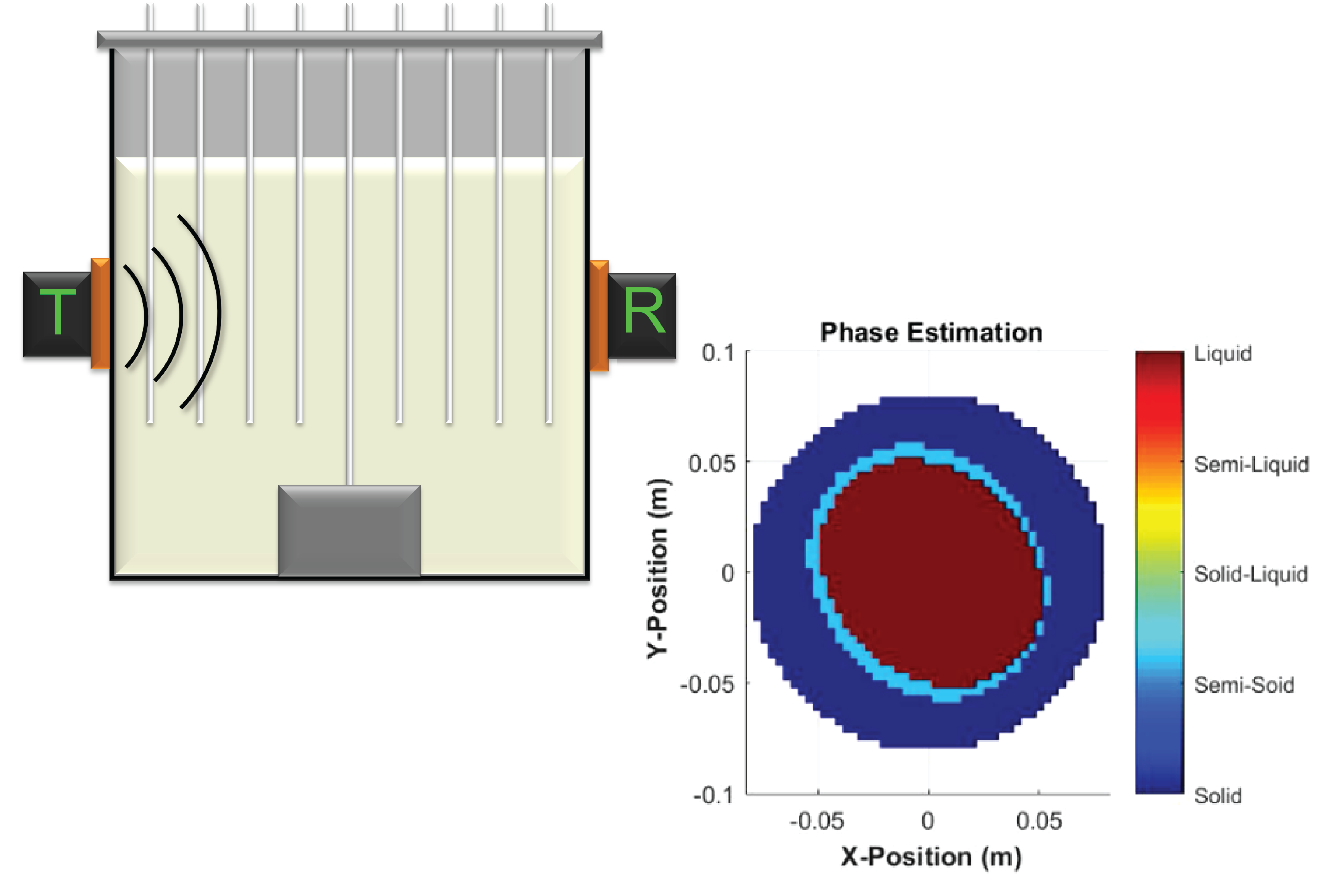

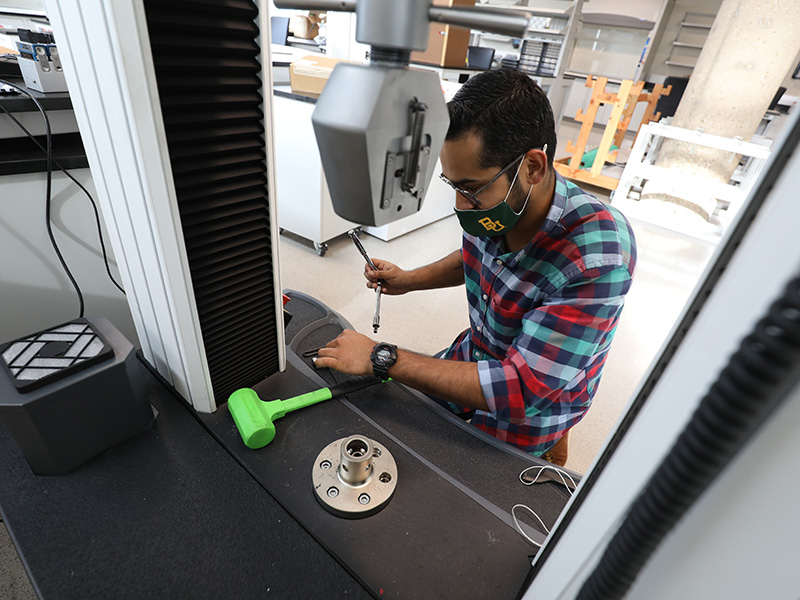

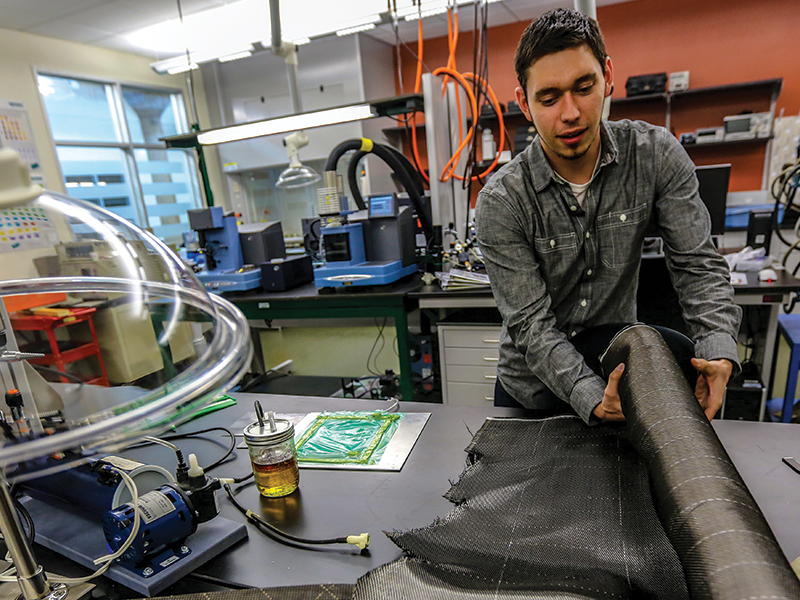

The Scientific Innovations in Complex Engineering Materials (Sic'em) research group specializes in current and next generation material systems that span from sub-micron to full-scale aircraft. Sic'em has expertise in characterization of complex composite systems coupled with predictive modeling from processing to final part performance. The Sic'em group is considered a leader in the numerical modeling of fiber reinforced polymer systems from processing to final product performance for systems from composite railroad ties, aerospace primary structure, automotive components, to sporting goods. The Sic’em group is also a leader in the creation of novel non-destructive testing methods, including ultrasonic, eddy current, and radiography, for composite and metallic systems providing high-resolution imaging of the internal microstructure. Sic'em researchers have developed twelve different FAA 8100-9 Statements Compliance with Airworthiness Standards. The NDE developed by the Sic'em team of researchers has produced six patents with eighteen additional patents pending.