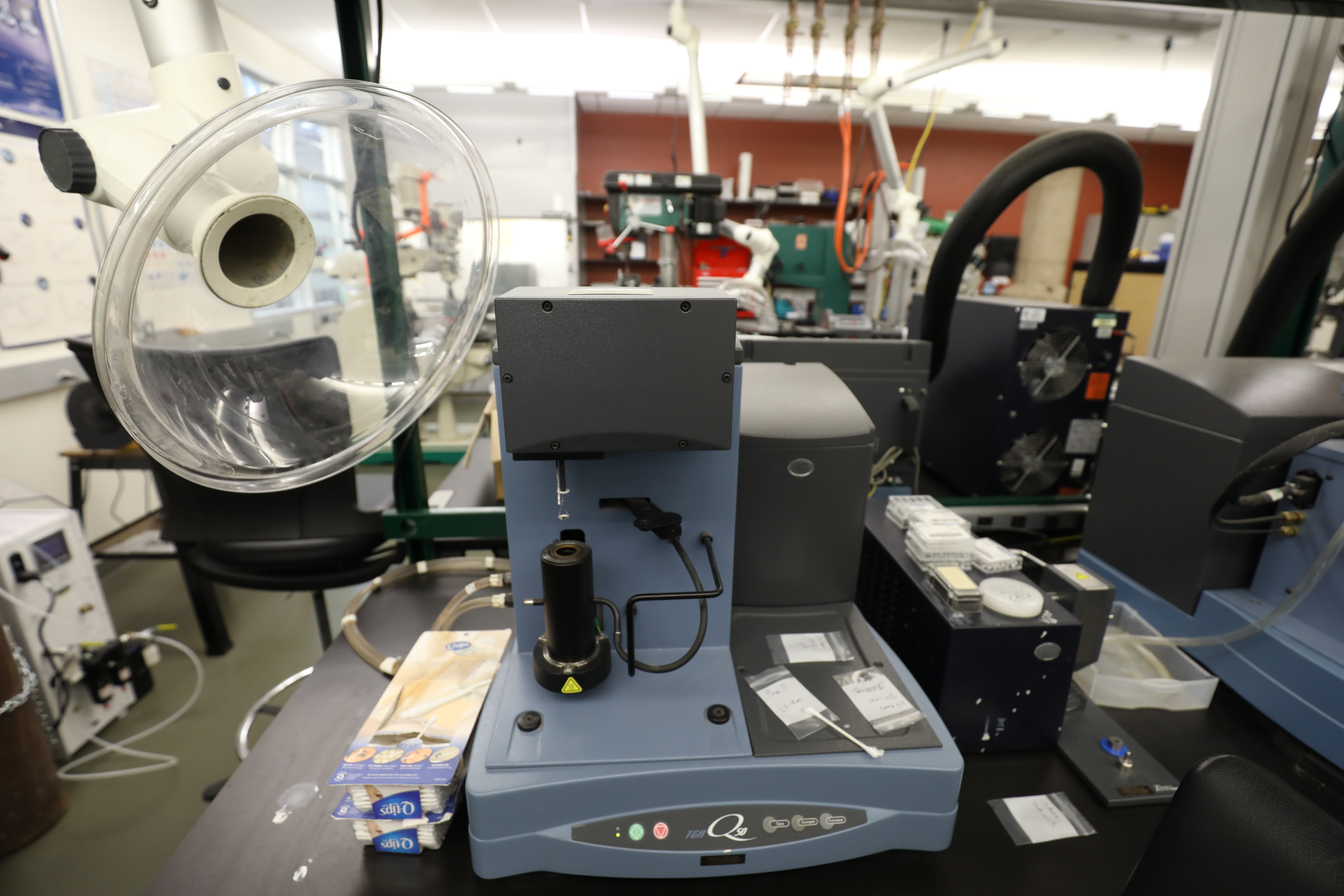

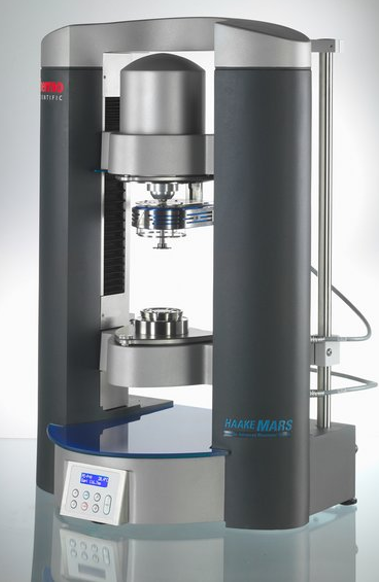

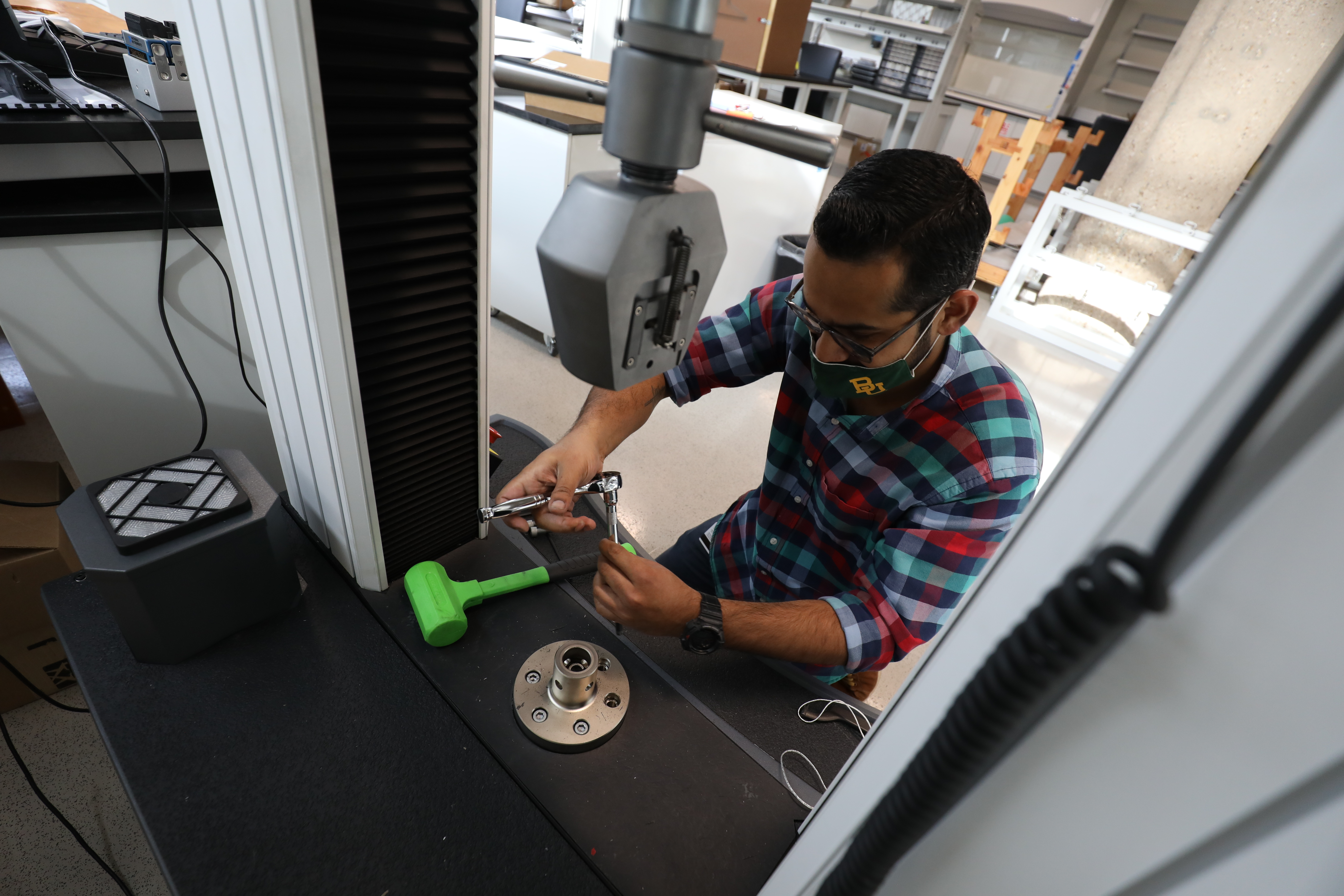

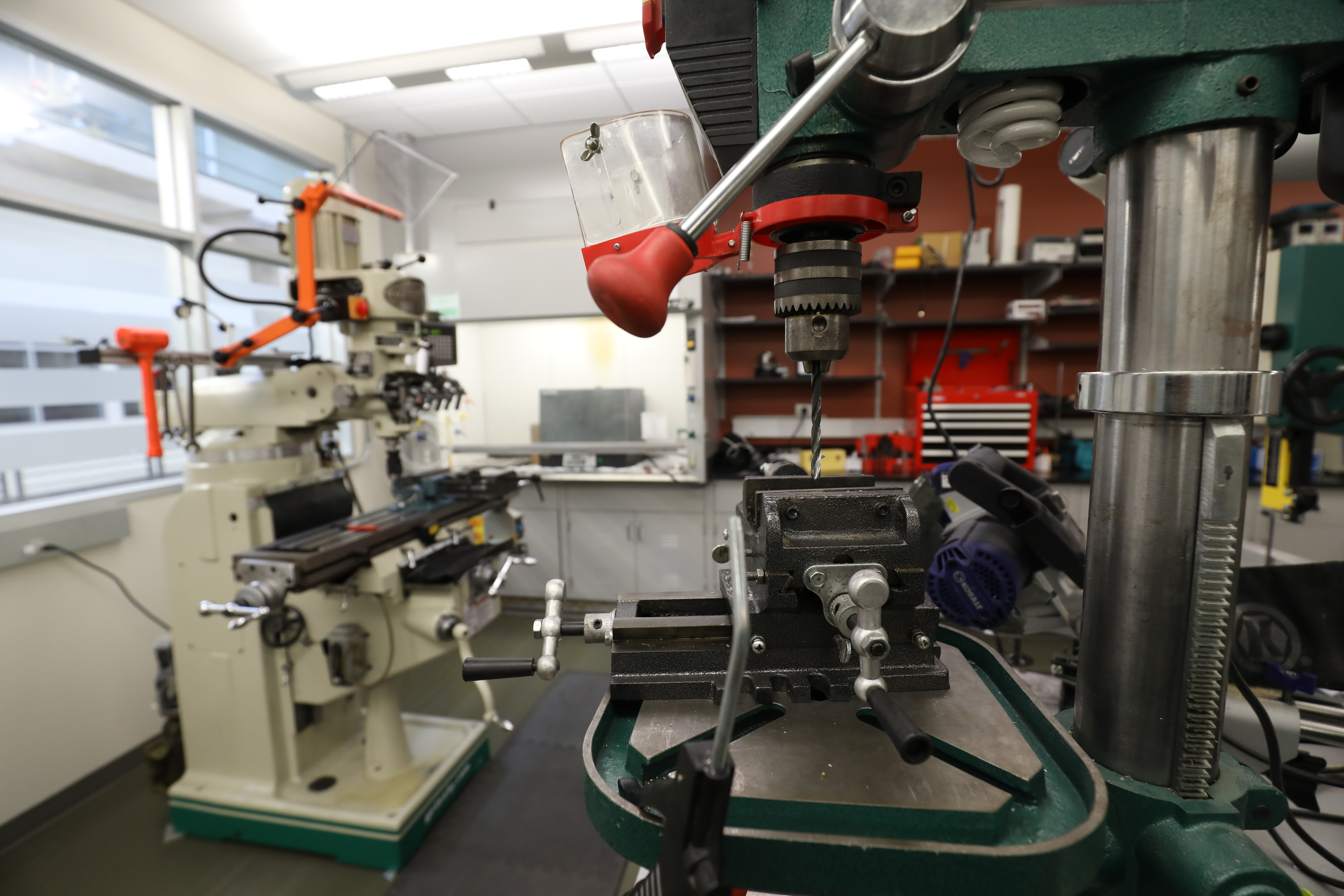

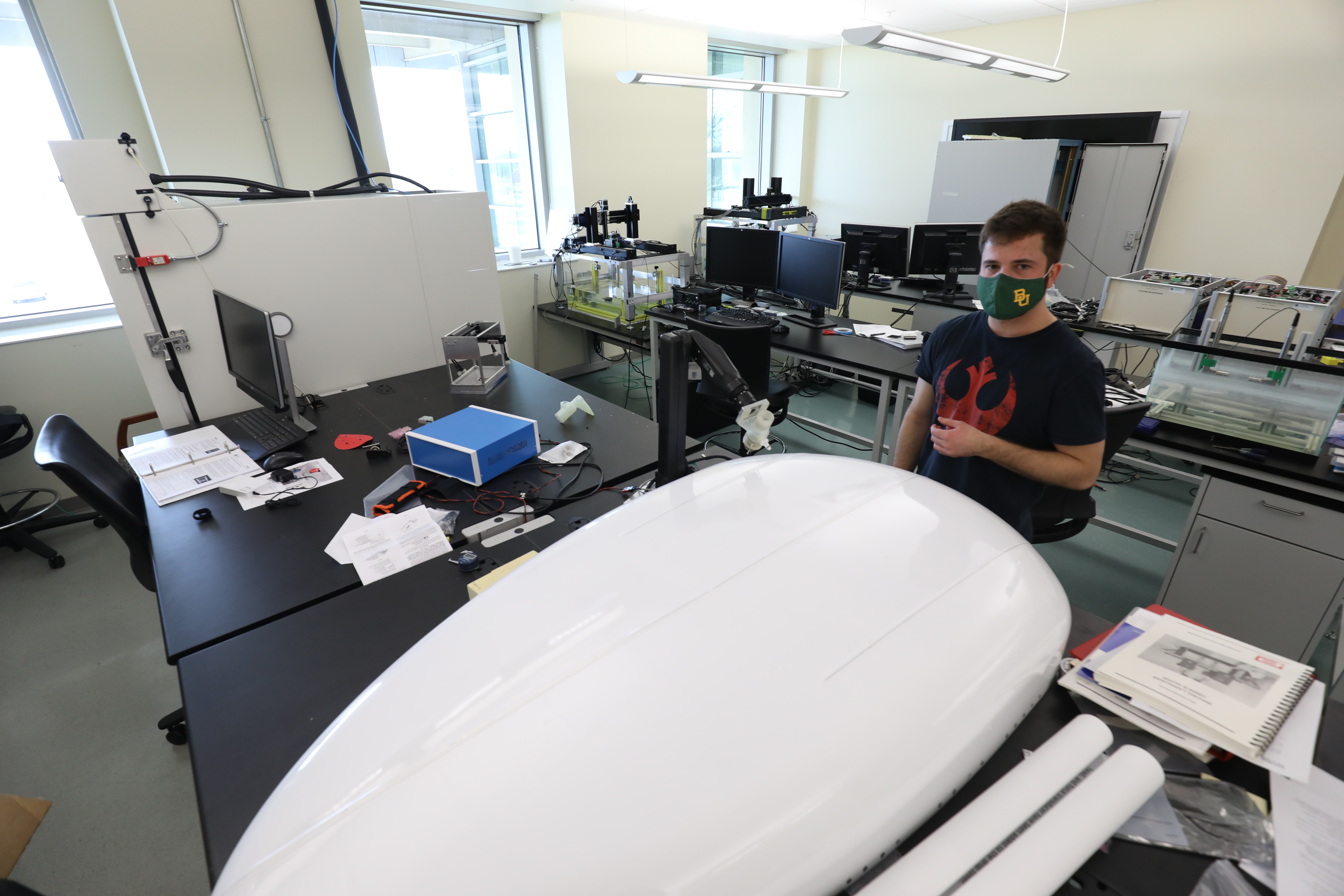

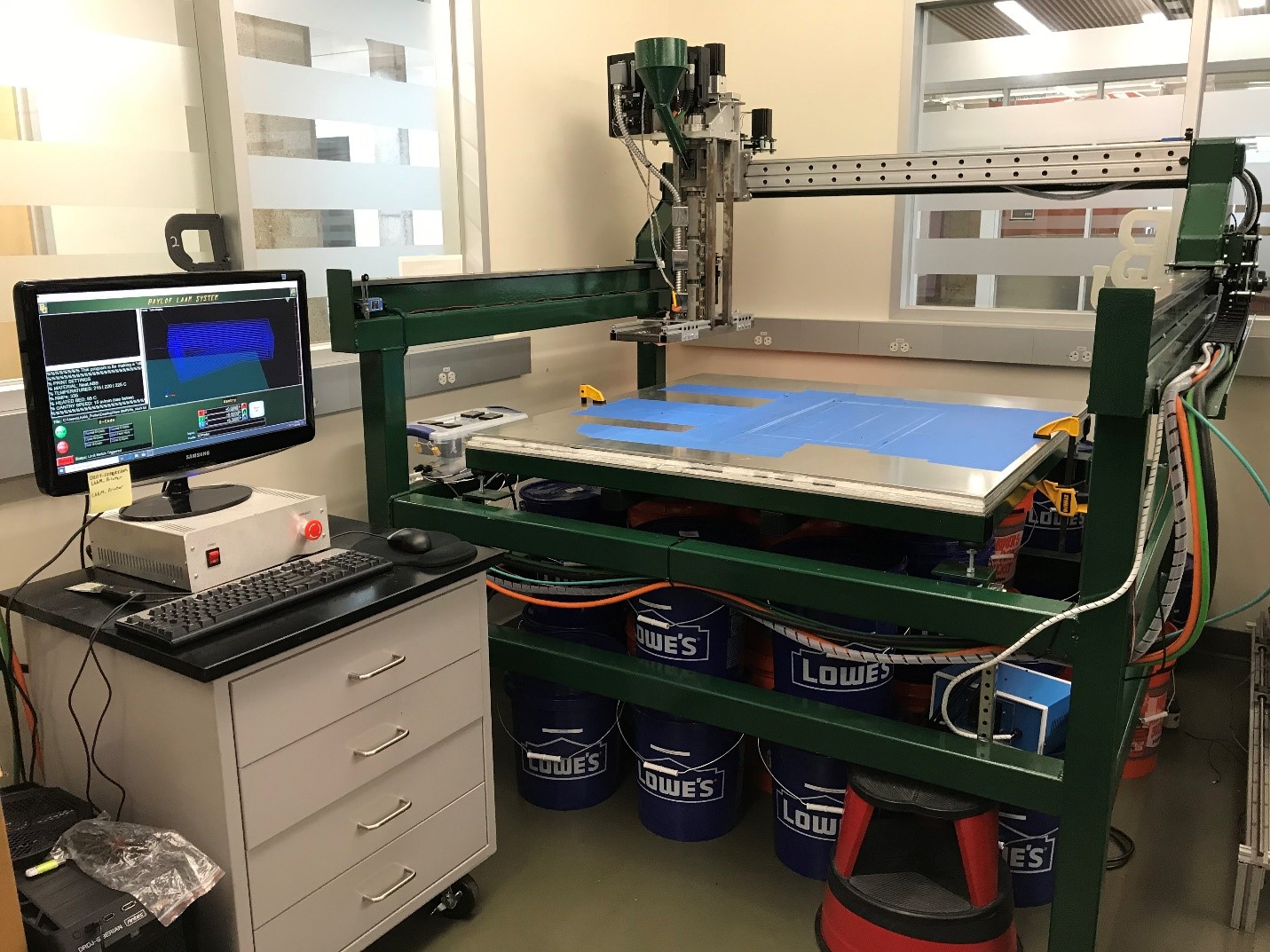

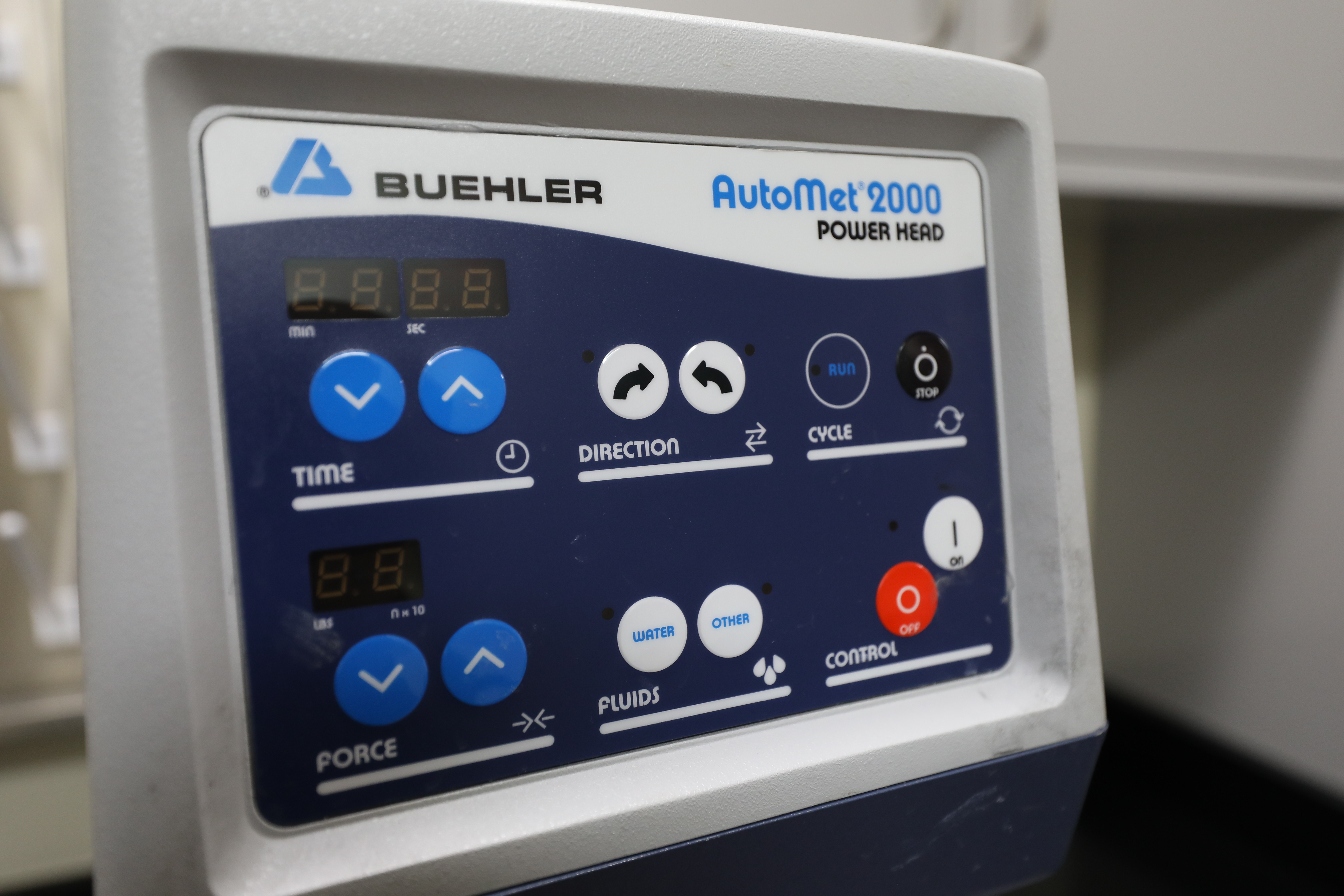

Sic’em has 12,000 sq. ft. of lab and office space with an additional 7,000 sq. ft. coming online through the 2023 calendar year at the BRIC (Baylor Research and Innovation Collaborative). The BRIC is a 330,000-square-foot facility optimized for both research and advanced prototypinghas with shared space for industry collaborations, workforce training, symposia and community events. The Sic'em group has dedicated space for materials synthesis, manufacturing, testing and chararacterization, NDE/NDI facilities, high-resolution imaging. Sic'em hosts Baylor's MTAC (Materials Testing and Characterization) facility, an ISO 17025 accrediated test laboratory.