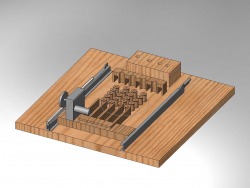

Final Design: Spool Stacker

The Operation Mongoose spool stacking machine operates using a single microcontroller to control three subsystems. These include what we refer to as: the hand, the cart, and the pipe-cleaners.

Subsystem I : The Hand and Wall

Components:

The hand subsystem consists of a cart that slides back and forth on a drawer slide. There is a motor attached to the cart that has a gear on its axile. The gear perfectly fits onto a timing belt, which allows the microcontroller to control the movement of the cart. The most important part of the hand is the wooden fingers, which are designed to slide in between the four sets of spools to seperate each set and allign them with the wall. The final part of the subsystem is the wall, which stops the spools in exactly the right place for pick-up.

Operation:

The hand subsystem starts on the outside edge of the circle, opposite the spools from the wall. The microcontroller turns on the motor, and slides the hand in between the spools, carrying them over to the wall. Once the spools reach the wall, the microcontroller tells the hand motor to take a few steps back in order to relieve friction on the spool against the wall. The pipe-cleaner subsystem then lowers into the first set of spools and picks them up. The hand subsystem then slides forward again to line the next set of spools against the wall and then takes a few steps back. This is process is done five times to place all twenty spools agains the wall for pick up by the pipe-cleaner subsystem. Once all spools are picked up, the microcontroller tells the the hand to return to its starting position.

Subsystem II : The Pipe-cleaners

Components:

The pipe-cleaner subsystem's most important component is four 5 1/2" copper tubes with 1/8" diameter that have four pipe cleaners threaded through them. The four tubes are drilled into a wooden block. The block also contains two larger tubes which have been centered in holes that have been drilled through the furthest ends of the wooden block. These tubes slide along metal rods that stabilize the movement of the system. The block is also connected to a timing belt system. The timing belt system consists of a long metal plate 1/2" wide x 18" long x 1/8" thick which has been connected to the cart at the top of the system. A free-moving gear rotates on an axil that is drilled into the metal plate at the end furthest away from the stage. The timing belt wraps around the free moving gear, up through the stage, and around a gear that is attached to the axil of the motor fixed to the stage.

Operation:

The pipe-cleaner subsystem's job is to pick up all the spools. First, the subsystem lower the wooden block containing the four pipe cleaners until the pipe-cleaners thread the first set of spools. Once the pipe-cleaners have threaded each spool, the subsystem then raises the block back up about two inches so that the first set of spools are now 2" off the ground. The system then pauses for a few seconds while the hand subsystem places four new spools against the wall. The pipe-cleaner subsystem then lowers the block back down two inches so that the pipe-cleaners now thread the second set of spools, stacking the first set of spools on top of the second set so that two sets of spools now thread the pipe-cleaner/rods. This process is then repeated for the remaining three sets of spools, stacking all five spools of each set ontop of each other. Once all the spool are on the pipe-cleaners, the block is raised all the way to the top of the systems. It then waits on the cart to move forward, and finally lowers the wooden block until the pipe cleaners slide through the holes of the pedestal.

Subsystem III : The Cart

Components:

The cart subsystem contains the pipe-cleaner subsystem, but operates seperately from it. It is composed of the stage (a piece of wood that fits onto a set of drawer slides), the two sets of drawer slides, a motor, and a timing belt attached to the wooden frame of the system. The cart subsystem is designed to control linear (forward and backward) movement of the cart. The movement of the subsystem is controlled by the motor that is attached to the cart. A gear is attached to the axil of the motor, which then fits into the timing belt that is attached to the frame of the system.

Operation:

The cart subsystem only moves a single direction during the spool stacking process. Once the hand and pipe-cleaner subsystems have completed picking up all the spools, the cart moves forward a few inches and stops. Once the entire process is complete, the cart system will move back into its original location.