Multifunctional and Advanced Materials

Sic'em

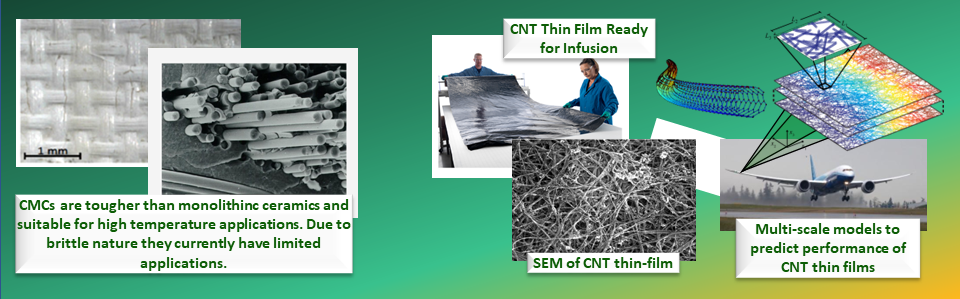

- Motivation – Current generation materials are unable to fulfill current and future needs in lightweighting, extreme temperature environments, and multifunctionality. The need to high temperature, high-strength materials crosses many industries that require advanced performance with the ability to utilize the same structure to satisfy multiple roles.

- Method/Approach – Custom manufacturing processes are being established to ensure tight process control for both ceramic matrix composite (CMC) structures for high temperature applications and multiscale hybrid composite systems integrating carbon nanotubes (CNT) within a polymer matrix composite.

- Highlights/Accomplishments – In the current scope of research we have accomplished:

- Models have been developed to serve as the basis for validation and to aid in experimental setup.

- Demonstrated success in modeling: (1) Full 3-D CNT network, (2) Coupled thermal and electrical effects, (3) Steady-state and transient responses for a variety of nanostructure configurations, and (4) Provided first reasonable explanation for observed premature failure of CNT networks.

- Impact testing of manufactured CMCs and CNT composite structures.

- Future Work - Multi-scale micromechanical modeling for low velocity damage in CMCs and Multi-scale/multifunctional models to understand micro-scale modifications. Microscale architecture modification during manufacturing for improved damage resistance to impact. Integrate thin-film CNT networks within polymer matrix composite structures.